PRODUCT

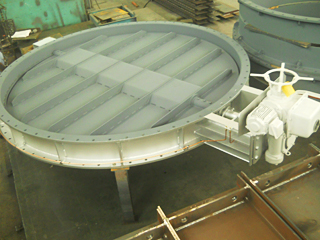

Butterfly Damper

Product Line

- Round or rectangular, diameter upto 3500mm, and the following types,

- 1) Normal Type : upto 350℃

- normal: metal touch / high close: packing

- 2) High Temperature Type : from 351℃ to 1300℃

- normal: metal tough / high close: packing

- 3) Anti-Erosion Type

- normal: metal touch / high close: packing

(Resin lining, Hastelloy lining, also available)

- 4) Anti-abrasion Type

- normal: metal touch / high close: packing

- Actuator: Air, Electrical, Hydraulic types are available.

Special features

- Keep low pressure-loss even upon full open.

Also mitigate disordered flow of air, gas, and others when flowing through dampers. - Wide control range of flow by selecting adequate blade feature and adequate actuator.

- Realize high close, using elastic sheet (close ratio: 99.9 ~ 99.98 % in case of 3000mm dia.)

- By our own design of seal construction, to keep high close, even temperature change of flow.

- Good for continuous operation.

Application

Air or Gas Duct in Boilers for power generation, Incinerators, Iron & Steel Plant, Cement Plant, Glass Making Plant, Oil Refinery, Deodorization Plant, Marine Boilers, etc.

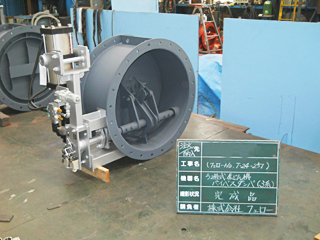

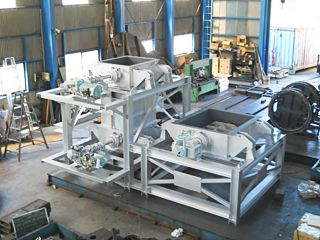

Louver Damper

Construction

Same as Butterfly Dampers, used for shut-off, flow-control and balancing of the flow. And in case of installation in a duct, it is easy to install in a narrow space.

- It consists of casing, blades, shaft, gland packing, sealing mechanism and actuators.

- Normally the blades are rotated 0 to 90 deg. and control or shut-off the flow.

There are two ways of the blade rotation,

Parallel Open-Shut ( for ON-OFF ) and Opposite Open-Shut ( for FLOW-CONTROL)

Product Line

- Round, diameter upto 5000mm or rectangular, from 1000mm up to 3500mm, and the following types,

- 1) Normal Type : up to 350℃

- normal: metal touch / high close: packing

- 2) High Temperature Type : from 351℃ to 1000℃

- normal: metal tough / high close: packing

- 3) Anti-Erosion Type

- normal: metal touch / high close: packing

(Resin lining, Hastelloy lining, also available)

- 4) Anti-Abrasion Type

- normal: metal touch / high close: packing

- 5) Double Louver Type

- TWO Single louver dampers arranged parallel in duct and ZERO leakage by seal air upon full close.

- 6) Tandem Louver Type

- Same construction as the double louver type but two blades on one shaft for cost saving.

- Actuator: Air, Electrical, Hydraulic types and Manual type are available.

Special features

- Have a buffer effect when full open.

Our blade design has effect to mitigate the flow disorder of air or gas. - Opposite Open-Shut type has a wide control range of flow by selecting adequate blade feature and adequate actuator, etc.

- Realize high close, using elastic sheet (close ratio: 99.9 ~ 99.95 % in case of 4000mm dia.)

- By our own design of seal construction, to keep high close, even temperature change of flow.

- Applicable as the control damper for large diameter duct.

Application

Air or Gas Duct in Boilers for power generation, Incinerators, Iron & Steel Plant, Cement Plant, Glass Making Plant, Oil Refinery, Deodorization Plant, Marine Boilers, etc.

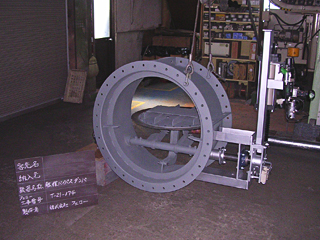

Single Flap Damper

Construction

Used for preventing reverse flow, in high close bypass duct and shut-off for maintenance.

Suitable for use in gas duct of dense dust.

- It consists of casing, blades, shaft, gland packing, sealing mechanism and actuators.

- Normally the blades are rotated 0 to 90 deg. and shut-off the flow.

Product Line

- Round or rectangular, both diameter up to 6000mm and the following types,

- 1) Normal Type:up to 350℃

- high close: packing

- 2) High Temperature Type

: from 351℃ to 450℃ - high close: packing

- 3) Anti-Erosion Type

- high close: packing

(Resin lining, Hastelloy lining, also available)

- 4) Anti-Abrasion Type

- high close: packing

- 5) Zero-Leak Type

- TWO blades and ZERO leakage by seal air between the blades.

- Actuator: Air, Electrical, Hydraulic types and Manual type are available.

Special features

- High Sealing

Ensure high sealing for long period by applying endless processing, using gum packing, metal packing and NASRON packing and also applying our unique design of blades. - Decrease the required torque

Decrease the torque by adjusting the shaft position, in comparison with standard flap damper and economical. - Protection of sealing part against dense dust

Movement of blades is ONE direction and by arranging the seals at downstream of the flow, avoid the direct contact of seals with the gas and mitigate the damages of seals. - Minimum pressure loss

Blade support is designed to mitigate the irregular flow and no partitions in the casing and realize the similar pressure loss to the butterfly damper upon full open.

Application

For prevention of reverse flow in stack fan, in Boilers for power generation, Incinerators, Iron & Steel Plant, Cement Plant, Oil Refinery, De-NOx, De-SOx plants, EP, Bag Filters, Coal Mills, etc.

Double Flap Damper

Construction

Used for preventing reverse flow, in high close bypass duct and shut-off for maintenance. Suitable for use in gas duct of dense dust.

- It consists of casing, blades (two), shaft (two), gland packing (two), sealing mechanism and actuators.

- Normally the blades are rotated 0 to 90 deg. and shut-off the flow.Since the blades are divided in two parts, upon full open, the sting-out of blades out of casing is short.

Product Line

- Round or rectangular, both diameter up to 6000mm and the following types,

- 1) Normal Type:up to 350℃

- high close: packing

- 2) High Temperature Type

: from 351℃ to 450℃ - high close: packing

- 3) Anti-Erosion Type

- high close: packing

(Resin lining, Hastelloy lining, also available)

- 4) Anti-Abrasion Type

- high close: packing

- Actuator: Air, Electrical, Hydraulic types and Manual type are available.

Special features

- High Sealing

Ensure high sealing by applying endless processing, using gum packing, metal packing and NASRON packing. - Protection of sealing part against dense dust

Movement of blades is ONE direction and by arranging the seals at downstream of the flow, avoid the direct contact of seals with the gas and mitigate the damages of seals. - Minimize the distance of damper

Since Two blades swing in the damper, compared with single flap damper, the damper width and weight can be reduced about half to one fourth. - Anti-abrasive effect

Protect blades, shaft and arms against abrasion by abrasive gas of clinker waste gas, sintering gas, and others as these parts are located behind the partition plate in the center of casing. - Realize Minimum pressure loss

Blade support is designed to mitigate the irregular flow and realize the low pressure loss.

Application

For prevention of reverse flow in stack fan, in Boilers for power generation, Incinerators, Iron & Steel Plant, Cement Plant, Oil Refinery, De-NOx, De-SOx Plants, EP, Bag Filters, Coal Mills, etc.

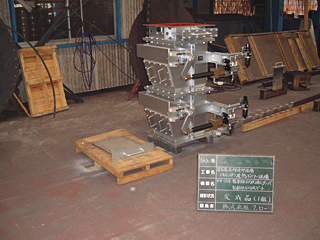

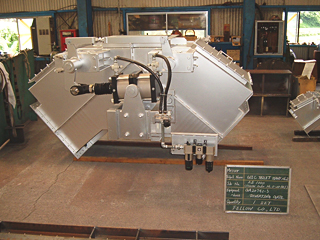

Slide Gate Damper

Construction

Used for shut-off in flue gas line of dense and sticky dust.

- It consists of casing, blade, shaft, gland packing, sealing mechanism and actuators.

- Normally the blades are moved same distance of duct diameter for shut-off.

- For shut-off method, by only packing, by using fastening bolts, by seal air or fastening cam.

- Moving the blades, by wire rope, by chain block, or using power, screw-rod, chain, wire rope, cylinder rod, etc.

Product Line

- Round or rectangular, both from diameter 300 mm up to 3500mm, and the following types,

- 1) Normal Type: up to 350℃

- normal: metal touch / high close: packing

- 2) High Temperature Type

: from 351℃ to 800℃ - normal: metal tough / high close: packing

- 3) Anti-Erosion Type

- normal: metal touch / high close: packing

( Hastelloy lining, also available )

- 4) Anti-abrasion Type

- normal: metal touch / high close: packing

- normal: metal touch / high close: packing

Special features

- normal: metal touch / high close: packing

- Minimize the width of damper.

No stick-out of blades in the duct upon open and shut motion. - Ensure the smooth open and shut.

By using the simple blade construction, minimize the distortion of blades by heat and ensure the smooth open and shut and apply the dust removal mechanism for high dust application.

(in case dust accumulation is foreseen, necessary to install cleaning hole and dust hopper) - Realize complete shut-off by using elastic seat and seal air.

- Open blade type, possible to check the conditions of the blade (such as distortion, erosion, etc.) upon full open.

Application

Air or Gas Duct in Boilers, Gas turbines for power generation, Incinerators, Iron & Steel Plant, Cement Plant, Glass Making Plant, Oil Refinery, Deodorization Plant, Marine Boilers, etc.

Other Special Dampers 1

Dampers for Powder Flow Control(Knife Gate/Rotary Valve/ Double Flap Damper)

Construction

Used for control ( ON-OFF ) of powder around Coal Mill, Bag Filter, Electric Furnace, Electrostatic Precipitator etc.

Either Flap type or Gate type available, depending on the characteristic of power, purpose, installation position.

Product Line

- Operated by Air Cylinder, Electrical Actuator, or Manual

- Usable up to 1000 ℃ ( water cooled) and Anti-Corrosion, Anti-Abrasion

- Usable for all the powders such as ash, cement, coal, dust in Steel Mill, etc.

Special features

- For Double Flap Damper, ensure enough angle of the flap for smooth flow of powder and make the volume capacity more than 200% to avoid any clogging.Also, keep the gap less than 0.1mm to have high sealing and help better efficiency of dust collectors.

- For Gate Valve, have 100% opening and then high cut or shut-off performance.

Other Special Dampers 2

Relief Valve, Diverter, Poppet Valve

Construction

Used for relieving too high pressure or diverting flow in the duct.

Equipped with either Air Cylinder, Electrical Actuator or Weight.

Product Line

- Applied from -20℃ to 1000 ℃

Anti-Erosion, Anti-Abrasion - ON-OFF operation

Special features

- For Gravity type with Weight, we can adjust to any pressure in the duct

- Ensure high sealing, using packing (gum, metal)

- Design to prevent any distortion of damper due to the difference of temperature inside and outside.

Construction

Most popular type of dampers and used for shut-off, flow-control and balancing of the flow. And in case of installation in a duct, it is easy to install in a narrow space.